Rule #1

Rule #1 for dogs, that they learn as puppies, is: Don't bite the hand that feeds you.

Humans have a different Rule#1 that they learn as babies.

Rule #1 for humans can be stated several different ways. The easiest way to say it is: Perfect Form at MMC. But what does that mean?

Humans have a different Rule#1 that they learn as babies.

Rule #1 for humans can be stated several different ways. The easiest way to say it is: Perfect Form at MMC. But what does that mean?

The way the ASME standard says it is: "the surface or surfaces of a regular feature of size shall not extend beyond a boundary (envelope) of perfect form at MMC."

The figures below illustrate Rule #1

The pin has an MMC size of 9.5 and an LMC size of 9.4. So no matter where you measure the pin, it must measure between 9.4 and 9.5.

If the pin is manufactured at a size that is less than 9.5, then it can be warped or otherwise have imperfect form as long as the entire pin fits within the 9.5 boundary.

If the pin is manufactured at 9.5, then it must have perfect form (straightness) in order to not violate the 9.5 MMC boundary.

The figures below illustrate Rule #1

The pin has an MMC size of 9.5 and an LMC size of 9.4. So no matter where you measure the pin, it must measure between 9.4 and 9.5.

If the pin is manufactured at a size that is less than 9.5, then it can be warped or otherwise have imperfect form as long as the entire pin fits within the 9.5 boundary.

If the pin is manufactured at 9.5, then it must have perfect form (straightness) in order to not violate the 9.5 MMC boundary.

For an internal Feature of Size, no matter where you measure the hole, it must be between 9.4 and 9.5. If the hole is manufactured at a size that is greater than 9.5, then it can be warped or otherwise have imperfect form as long as the entire hole stays outside the 9.4 boundary.

If the hole is manufactured at 9.4, then it must have perfect form (straightness) in order to not violate the 9.4 MMC boundary.

If the hole is manufactured at 9.4, then it must have perfect form (straightness) in order to not violate the 9.4 MMC boundary.

Note that Rule #1 does not specify any requirement for location or orientation.

Also note that rule #1 can be overridden by either the Independency symbol or by a note stating that perfect form at MMC is not required.

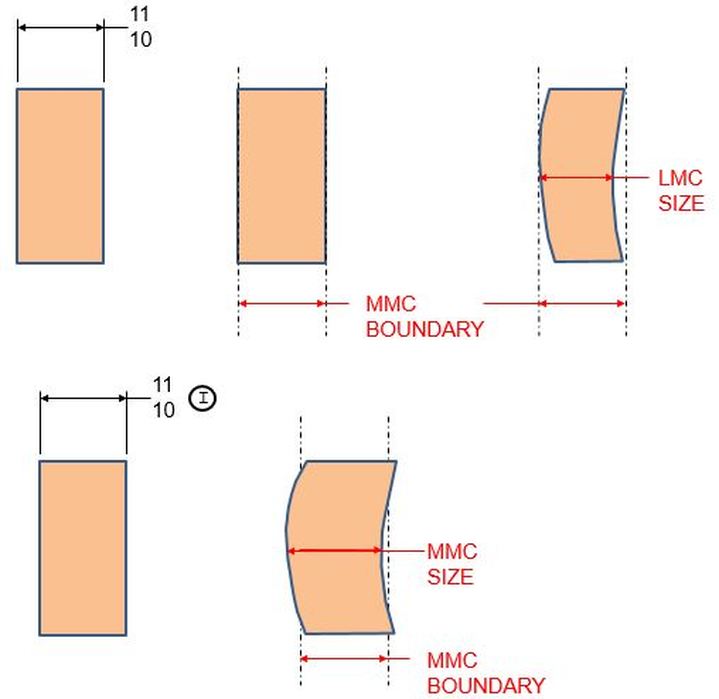

The figure below shows a part with and without the Independency symbol. The Indpendency symbol is the I inside a circle. Without it, the part is required to always stay inside the MMC boundary. But with the Independency symbol, the part is allowed to violate the MMC boundary. The part is still always required to stay within the required size limit everywhere on the part. But it is allowed to be at its MMC size and also be warped such that it violates the MMC boundary.

Also note that rule #1 can be overridden by either the Independency symbol or by a note stating that perfect form at MMC is not required.

The figure below shows a part with and without the Independency symbol. The Indpendency symbol is the I inside a circle. Without it, the part is required to always stay inside the MMC boundary. But with the Independency symbol, the part is allowed to violate the MMC boundary. The part is still always required to stay within the required size limit everywhere on the part. But it is allowed to be at its MMC size and also be warped such that it violates the MMC boundary.

A straightness or flatness requirement can also override Rule #1. Applying straightness or flatness to the Feature of Size will result in a new boundary that cannot be violated. We will learn what this means in a future section.